The flat deck barge, a vital asset in marine construction, is currently experiencing high demand on Canada’s West Coast due in part to the current abundance of large marine construction projects. These vessels, characterized by their flat-bottomed hulls and clear flat decks, are essential for transporting various cargo and are typically moved by tugboats.

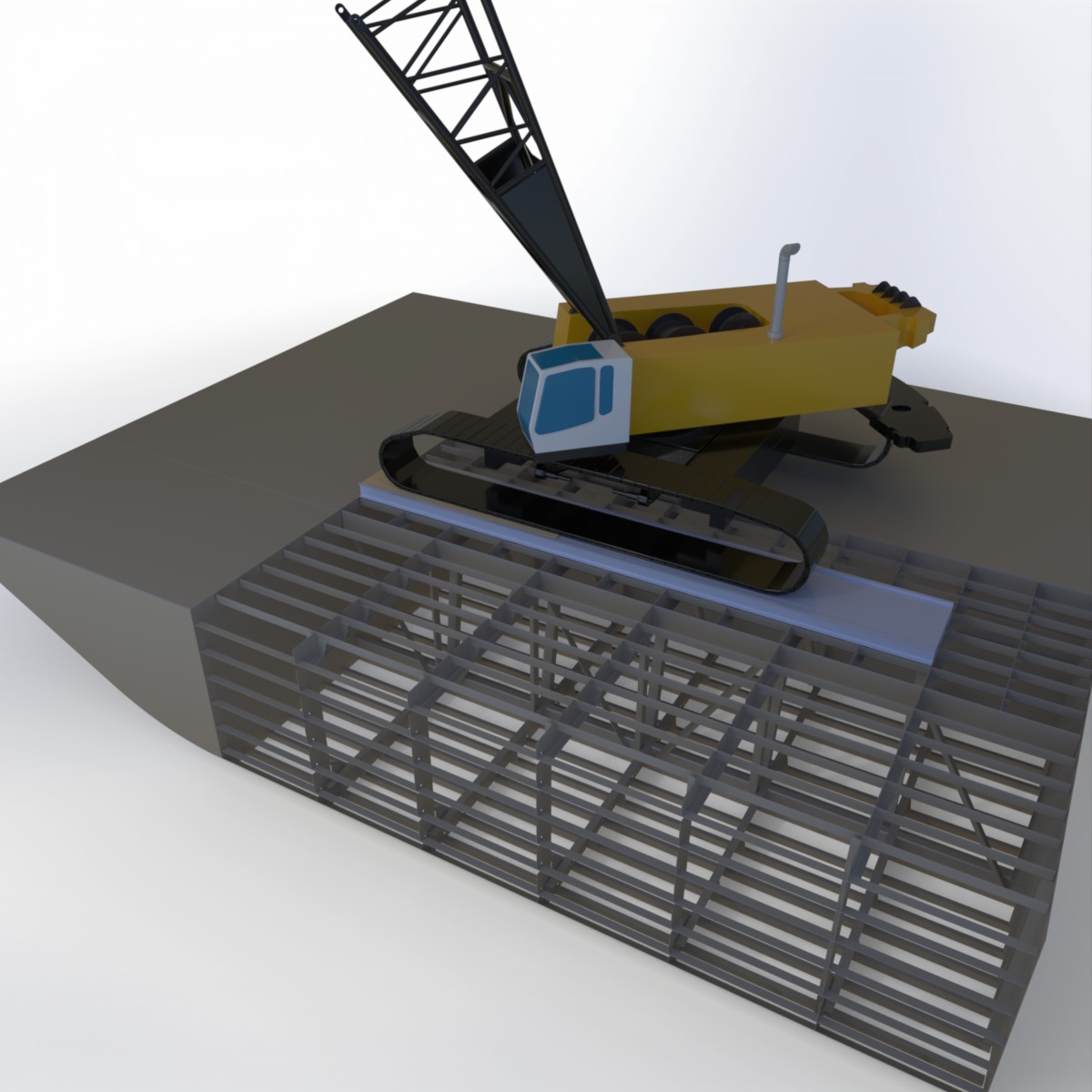

There are many examples of flat deck barges that have been purpose-built for use in the marine construction industry. These barges are designed specifically for the support of heavy equipment such as crawler cranes and excavators. These purpose-built barges will be outfitted with mooring equipment in the form of spuds or anchor winches. They will often have some sort of crew shelter and on-board power. Hidden from sight, these barges will have internal structures suited specifically to support the intended use.

In British Columbia, as in most regions, regulations mandate that every barge and crane combination be evaluated by an engineer or crane manufacturer to ensure safe operation. This evaluation includes assessing the stability of the floating support and confirming that the barge has been designed to handle the proposed crane’s type and capacity.

Although many purpose-built construction barges exist on the west coast, most available barges are designed to support bulk materials such as woodchips and gravel. These barges are typically rated in terms of a total deadweight capacity and a deck pressure or tonnes per square meter.

The process of designing a barge for bulk cargo has been well established through many decades of history and is well described in classification society rules. In simple terms, the builder will need to construct a simple watertight hull capable of withstanding the compression from the deck cargo above and hydrostatic pressure below in addition to the bending moments induced by sea travel.

Converting a deck barge designed for bulk cargo into a work platform for construction introduces unique structural challenges. These floating platforms must accommodate various heavy machinery, including pumps, mooring winches, piles, and crawler cranes. Often these heavy machines have been designed for operating on firm level soil which would provide uniform support and benefit from large contact areas. With the trend for increasing lifting requirements on worksites these machines become large enough to exert forces on the barge deck that are far higher than the barges advertised deck capacity and warrant a detailed evaluation.

The engineer will consider what loads will be imposed by the equipment. These loads may be reactions at a foundation, pressures from heavy tire loads, outrigger loads, or reactions from machine crawlers. This pressure will be much higher than the total weight divided over the total contact area due to the center of gravity eccentricity that occurs during machine operations. This can require an in-depth analysis of the machines proposed operation and may require the engineer to use estimated weights and centers to determine how forces will bear on the barge.

The engineer will then consider how these loads align with the structures that support the deck plate. Their analysis will differ from the design methods used for barges designed for bulk cargo. The load will now be highly concentrated, and the barge will not benefit from a nearly equal hydrostatic pressure below the cargo.

It can be insightful to picture the barge with the shell plate removed to imagine what is holding up the proposed machine. In this exercise we won’t ignore the contribution of that plate, but we recognize that it is the below deck structures that are of primary importance. The required analyses vary depending on the complexity of the supporting arrangement. For purpose-built barges the arrangements often allow first principle evaluations of major structures. When repurposing barges the analyses may require finite element models to ensure the structures can safely support the machine due to the complex interactions involved in the load distribution and deflections involved.

The outcome of the analysis can vary. For some small machines where under deck structures are nearly sufficient for supporting the machine, timber crane mats may provide enough additional load distribution. For large machines or situations where the load lands on areas of insufficient support, additional steel structures will be required. Depending on the situation this could involve an assortment of modifications such as beams on deck, pillars below deck, or additional non watertight bulkheads.

When the installation of very large machines, such as ringer cranes, are evaluated onboard barges the global longitudinal strength may become a limiting factor. This refers to the barges ability to support the load without bending along its length. This concern speaks volumes about the incredible reactions these machines can produce.

While the construction barges on B.C.’s coast may appear similar from the outside, significant engineering considerations are involved in their evaluation and structural design to ensure their safe operation.